Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Packaging: Carton box

Productivity: 1000000 pcs/week

Transportation: Ocean,Land,Air,Express

Place of Origin: China

Supply Ability: 1000000 pcs/week

Certificate: GB/T19001-2008/ISO9001:2008

HS Code: 8541401000

Port: SHENZHEN

Payment Type: T/T,Paypal

Incoterm: FOB,EXW,FCA

Model No.: 1004FRD62D3L12

Brand: Best LED

Supply Type: Original Manufacturer

Place Of Origin: China

Species: Led

Package Type: Through Hole

Forward Current IF Of 10mm Red LED: 30ma

Chip Material Of 10mm Red LED: AIGaInP

Forward Voltage Of 10mm Red LED: 2.0-2.4v

Lens Type Of 10mm Red LED: Diffused Red Lens

LED Type: Mini Led Red Lamps

Emiting Type: Led Lamps

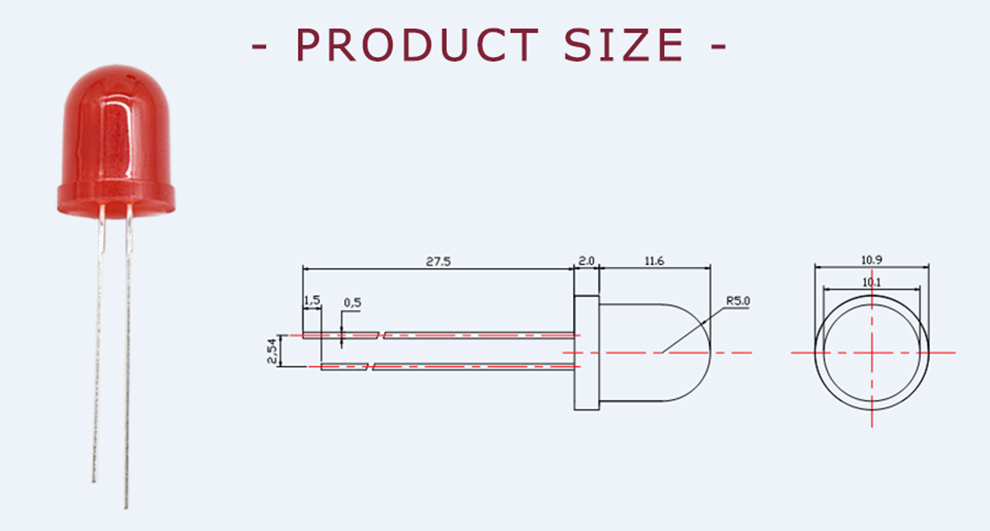

Pin Length: 27/29mm

Brightness Level: High brightness

Viewing Angle: 40 degree

| Selling Units: | Piece/Pieces |

|---|---|

| Package Type: | Carton box |

High Bright 10mm red diffused led with 625nm LED Wavelength:

There have kinds of brightness level for the LED Lamps (or SMD LED ), sometime even the the LED looks exactly the same in the out side, as long as you light it up you will find the different. The brightness is depends on the chip when the LED got the same shape, lens type and size. Normally, the bigger size of LED chip, the more brightness and more high power we can get from the LED. This 1004FRD62D3L12 just got one level lower than 1004FRD62D3L14, there will have about 500-800mcd different between them. For some project that don't need that much brightness, this way will save more cost from the material.

If you need some 10mm Red Through-Hole LED for your project, please feel free to contact us~

10mm mini LED Red Through-Hole LED Size:

Red Through-hole LED Features:

* Dimension of Lens: 10mm;

* Wavelength 620-630nm;

* Lens type: Deep Red diffused;

* High reliability and high radiation intersity;

Electrical Parameters:

| Parameter | Symbol | Rating | Unit |

| Power Dissipation | Pd | 0.09 | W |

| Forward Voltage | VF | 2.0-2.4 | V |

| Operating Temperature | Topr | -25 ~ +80 | ℃ |

| Storage Temperature Range | Tstg | -40 ~ +80 | ℃ |

| Soldering Temperature | Tsol | Reflowing soldering: 260℃ for 5 seconds Hand soldering: 300℃ for 3 seconds | ℃ |

| Electro-Static-Discharge(HBM) | ESD | 1000 | V |

| Service life under normal conditions | Time | 80000 | H |

| Warranty | Time | 2 | Years |

| Antistatic bag | Piece | 500 or 1000 | Bag |

* Pulse forward current condition: Duty 1% and pulse width=10us.

* Soldering condition: Soldering condition must be completed with 3 secongds at 260℃

Electrucal Optical Characteristics(Tc=25℃)

| Parameter | Sysmblo | Min | Typ | max | Unit | Test Conditin |

| Voltage | V | 2.0 | - | 2.4 | V | --------- |

| Luminous Intensity | IV | 3000 | 3500 | 4000 | mcd | 20mA |

| Peak Wavelength | λP | | 625 | | nm | 20mA |

| Dominant Wavelength | λD | 620 | 630 | nm | 20mA | |

| Viewing Half Angle | 2θ1/2 | | 40 | | deg | 20mA |

*Luminous Intensity is measured by ZWL600.

*θ1/2 is off-sxis angle at which the luminous intenity is half the axia luminous intensity;

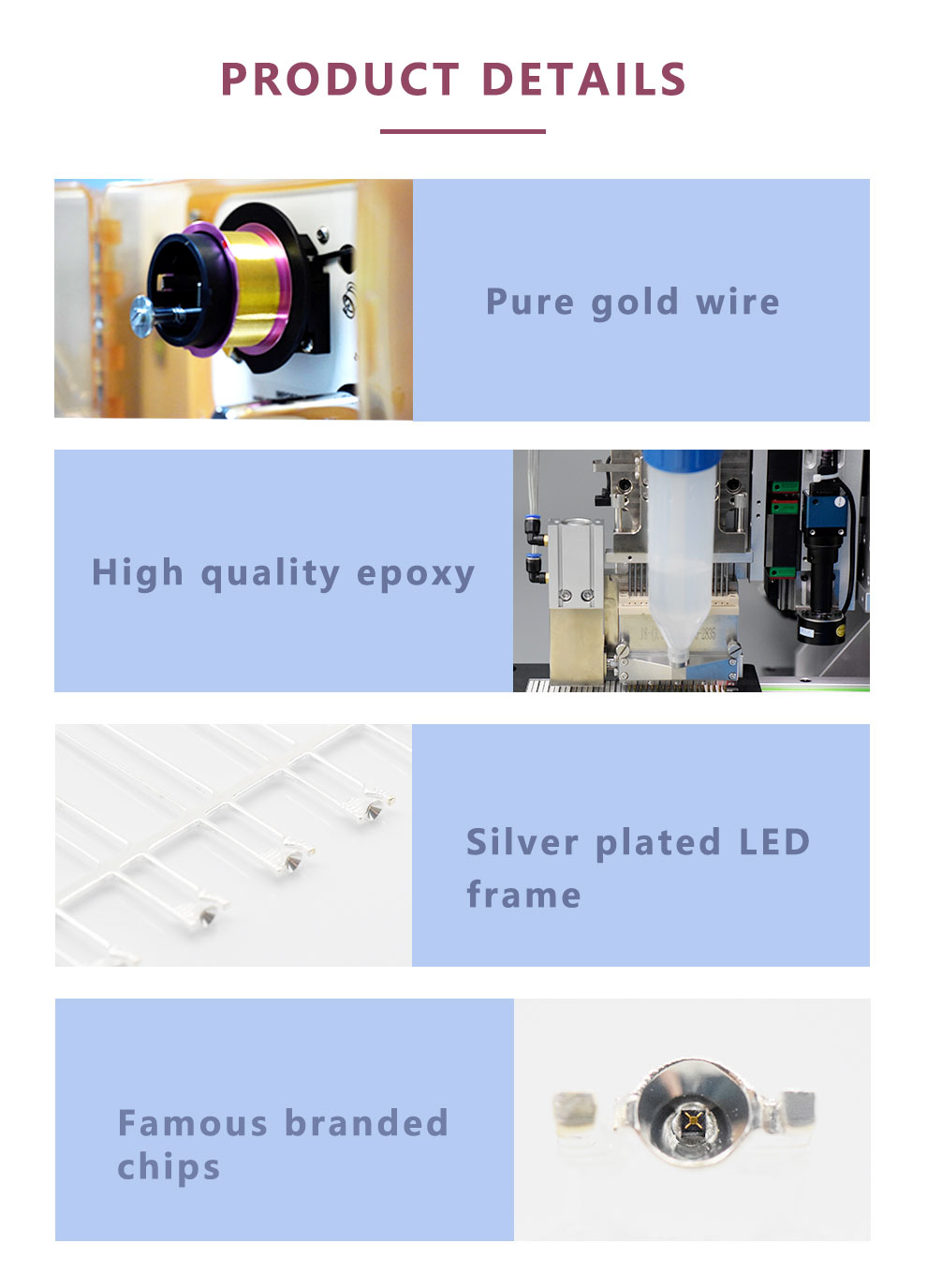

Material of Red through-hole LED:

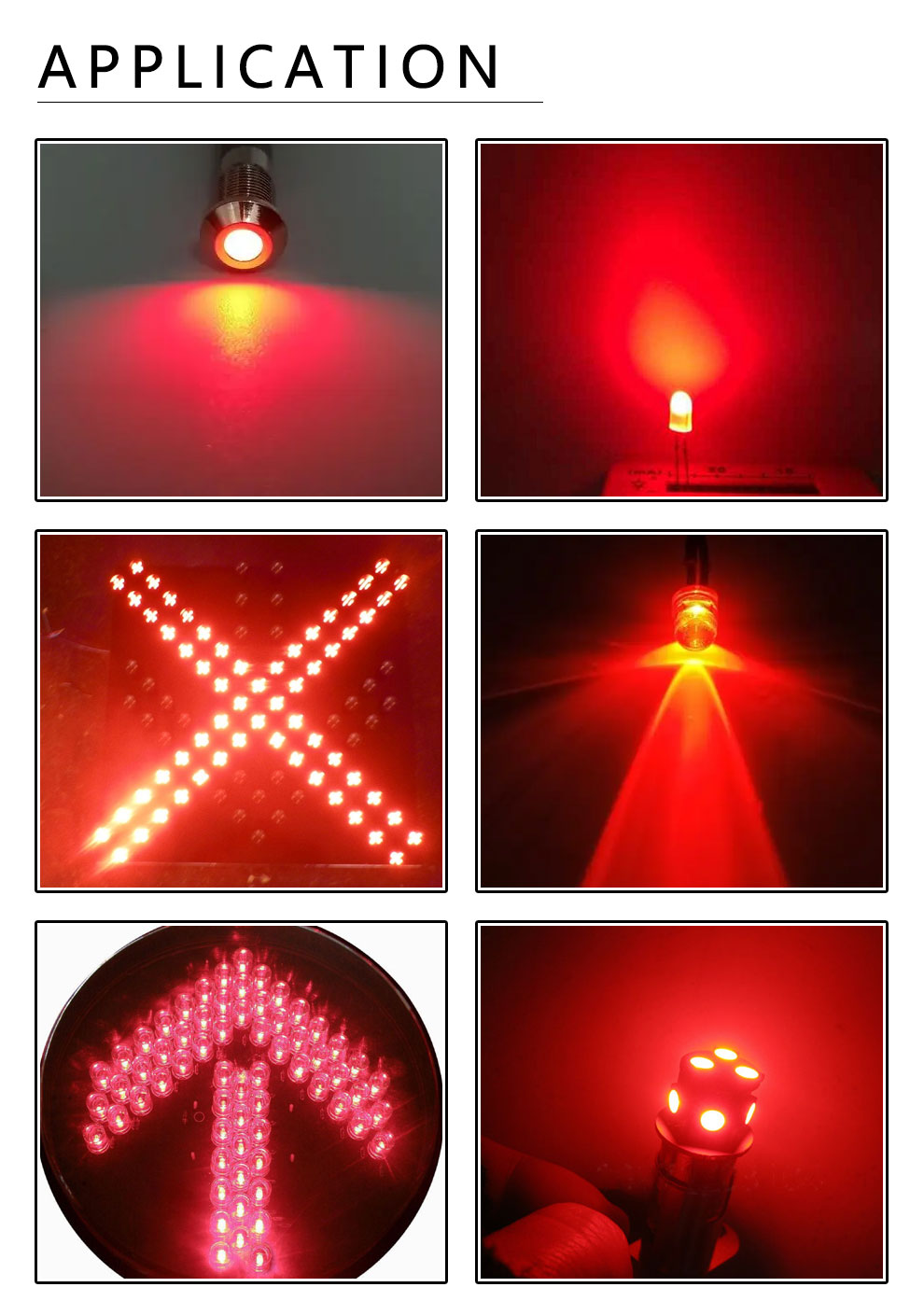

Application:

LED DIY project;

LED lighting project;

LED Back light;

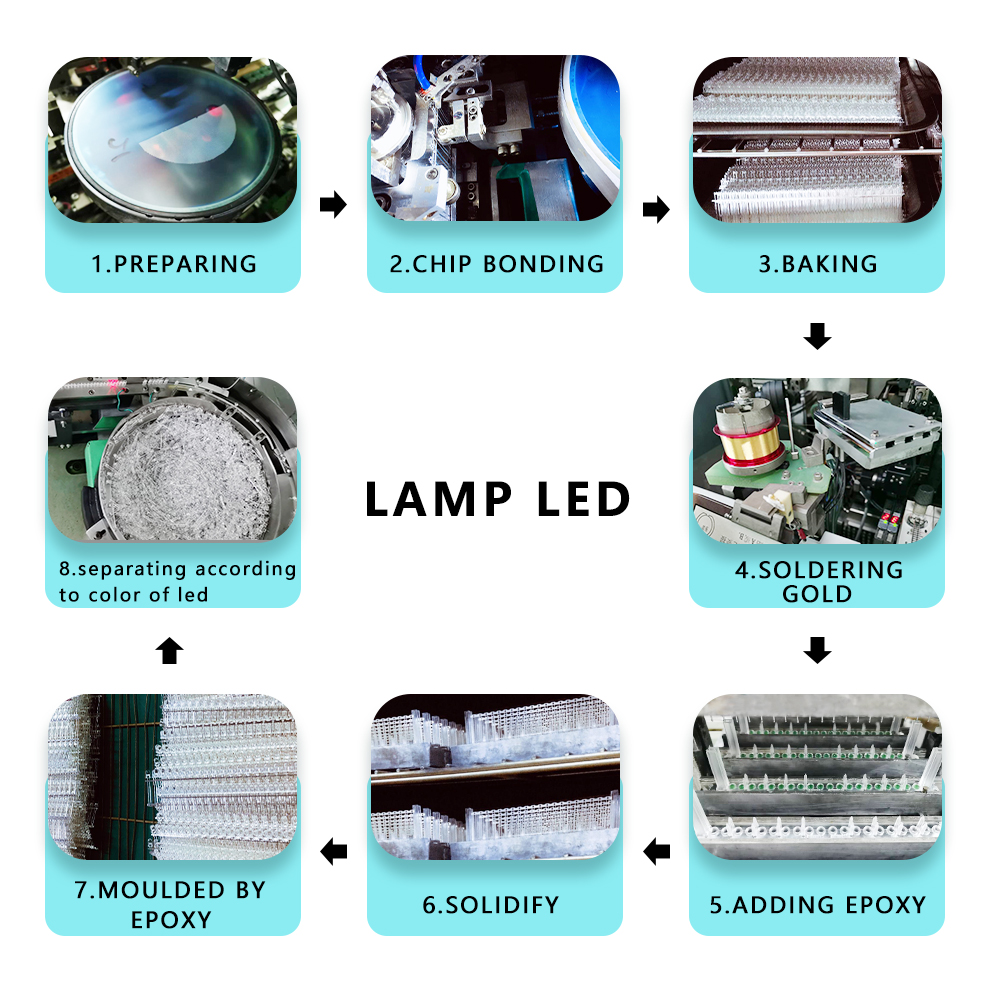

Manufacturing progress of Through-hole LED:

Compare with SMD LED, through-hole LED production will be more complicated. Which means it will take more production progress and production time:

First of all, we need to prepare the LED chip(this will be same as SMD LED production); Secondly, we will need to put the LED chip into the LED frame, and then we will need the pure gold wire to connect the cathode and anode of LED frame. There comes different, For SMD LED production, we need to put the epoxy to LED frame and wait until it dry by oven. However, for LED Lamps, we need to inject epoxy into the mold of lens and put all the things to oven for at least 8 hours until they dry. After that, we need to tae them from the oven and get the LED out of mold. And then we need to cut the pins of LED so that they can be easy to test.

Finally, we got the LED. In order to make sure the quality and the uniform as good as required. We also need to put all the LED to the separation machine and them we will got the LED with same bins.

Storage Conditions:

1. avoid continued exposure to the condensing moisture environment and keep the product away from rapid transitions in ambient temperature;

2. LEDs should be stored with temperature ≤30℃ and relative humidity<60%℃;

3. Product in the original sealed package is recommended to be assembled within 72 hours of opening;

4. Product in opened package for more than a week should be baked for 6-8 hours at 85-10℃;

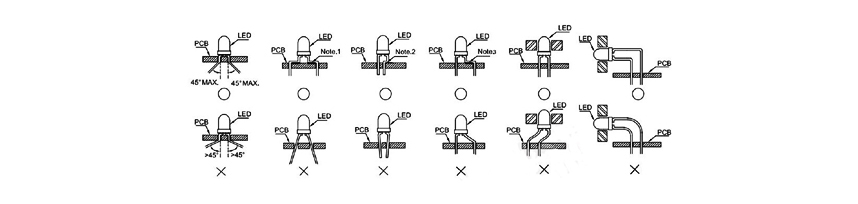

LED MOUNTING METHOD

1, The lead pitch of the LED must match the pitch of the mounting holes on the PCB during component placement;

Lead-forming may be required to insure the lead pitch matches the hole pitch;

Refer to the figure below for proper lead forming procedures;

Do not route PCB trace in the contact area between the leadframe and the PCB to prevent short-circuits;

Noted:

○ Correct mounting method;

× Incorrect mounting method;

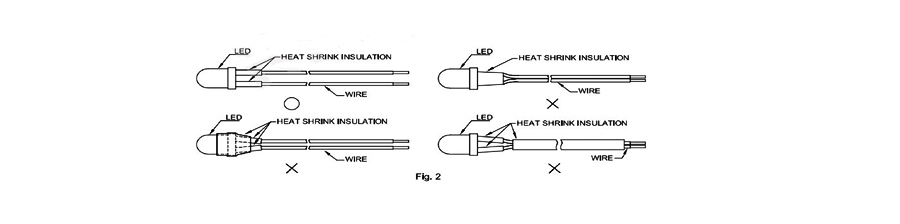

2. When soldering wires to the LED, each wire joint should be separately insulated with heat-shrink tube to prevent short-circuit contact.

Do not bundle both wires in one heat shrink tube to avoid pinching the LED leads;

Pinching stress on the led leads may damage the internal structures and cause failure;

Noted:

○ Correct mounting method;

× Incorrect mounting method;

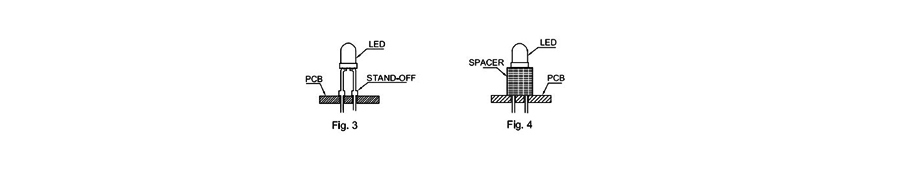

3. Use stand-offs(Fig 3)or spacers(Fig 4)to securely position the LED above the PCB;

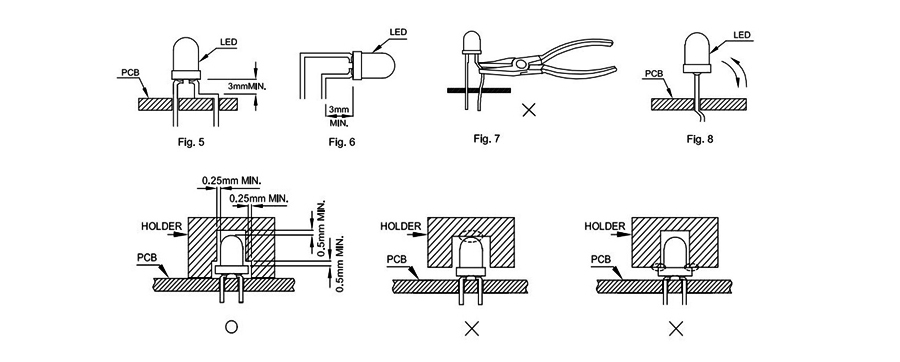

4. Maintain a minimum of 3mm clearance between the base of the LED lens and the first lead bend (Fig. 5. Fig. 6)

5. During lead forming, use tools or jigs to hold the leads securely so that the bending force will not be transmitted to the LED lens and its internal structures;

Do not perform lead forming once the component has been mounted onto the PCB;

Lead Forming Procedures

1. Lead Forming Procedures;

2. Do not bend the leads more than twice (Fig. 7);

3. During soldering, component covers and holders should leave clearance to avoid placing damaging stress on the LED during soldering(Fig 8);

4. The tip of the soldering iron should never touch the lens epoxy;

5. Through-hole LEDs are incompatible with reflow soldering;

6. If the LED will undergo multiple soldering passes or face other processes where the part may be subjected to intense heat please check with Best LED for compatibility;

Tel: 86-0755-89752405

Whatsapp: +8615815584344

Address: No.3, Lida alley, Qiuwu community, Longgang District, Shenzhen, Guangdong, China. 518116, Shenzhen, Guangdong China

Website: https://www.bestsmd.com

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.